Trust Osk WPC Flooring Supplier for Contaminant-Free Products

In today's global manufacturing landscape, the pursuit of sustainable practices sometimes encounters complex challenges that require diligent oversight and ethical commitment. Recent discussions within industrial circles have raised questions about certain sourcing practices where the origin and purity of recycled components remain inadequately documented. This troubling situation highlights why businesses must exercise careful discernment when selecting their production partners. The crucial importance of partnering with a thoroughly vetted WPC Flooring Supplier cannot be overstated for companies genuinely committed to environmental stewardship and product safety. When suppliers prioritize cost reduction over material verification, they potentially compromise the integrity of the entire production cycle. The distinction between exemplary suppliers and ordinary vendors often resides in their unwavering dedication to comprehensive material tracing and purity validation. This foundational commitment to transparency and safety establishes trustworthy business relationships that benefit all participants in the supply network. Commercial enterprises that comprehend this essential truth proactively seek supplier alliances based on shared principles of responsibility and quality assurance.

The concept of recycling within manufacturing carries profound implications for environmental protection and human wellbeing. Authentic recycling practices involve meticulous sorting and purification processes that eliminate potentially eliminate potentially harmful substances before materials enter new production cycles. Unfortunately, some market participants may bypass these crucial steps in their eagerness to capitalize on market trends. This misguided approach undermines the very purpose of ecological manufacturing and betrays consumer confidence. Reputable suppliers recognize that their responsibility extends beyond merely providing materials to ensuring those materials meet the highest standards of composition and safety. This expanded understanding of supplier responsibility inspires implementation of sophisticated verification protocols at multiple procurement stages. Modern supply management incorporates advanced tracking mechanisms that monitor material origins and processing history. This surveillance capability permits preventive actions before questionable materials enter manufacturing streams. The supply industry continues progressing toward greater accountability and traceability across all operational dimensions. This evolutionary trajectory reflects growing awareness that supplying materials must harmonize with health protection rather than operate separately from safety considerations.

Supplier selection represents one of the most significant decisions businesses make in their operational planning. Organizations that emphasize material provenance and testing procedures typically experience fewer complications in their manufacturing outcomes and maintain stronger marketplace reputations. The assurance derived from collaborating with verified suppliers empowers companies to concentrate on their primary business goals without persistent anxiety about material quality. The changing character of international environmental standards necessitates continuous vigilance and adaptation from all contributors to the global economy. Supplying entities that remain knowledgeable about these evolving benchmarks provide indispensable support to their industrial clients. This supportive dynamic grows especially valuable when maneuvering through the intricate requirements of different markets and regulatory environments. The consistent execution of sound verification principles distinguishes industry pioneers from other market players. This differentiation becomes particularly apparent when examining how different suppliers manage the documentation requirements for raw material batches. The variation in methodology frequently determines frequently determines whether manufacturing proceeds smoothly or encounters difficulties during quality assessment processes.

Supply excellence encompasses not only material quality but also every facet of the business partnership, including administrative precision and procedural correctness. Enterprises that appreciate this complete comprehension of supplier relationships place themselves for sustained expansion in competitive international arenas. This forward-looking strategy toward business collaborations mirrors a sophisticated grasp of contemporary commerce prerequisites and customer anticipations regarding business ethics and operational openness. This inclusive viewpoint on supply chain partnerships reflects the transforming expectations of worldwide consumers who progressively value transparency and ethical business conduct alongside traditional quality metrics. This comprehensive outlook informs every aspect of responsible supply operations.

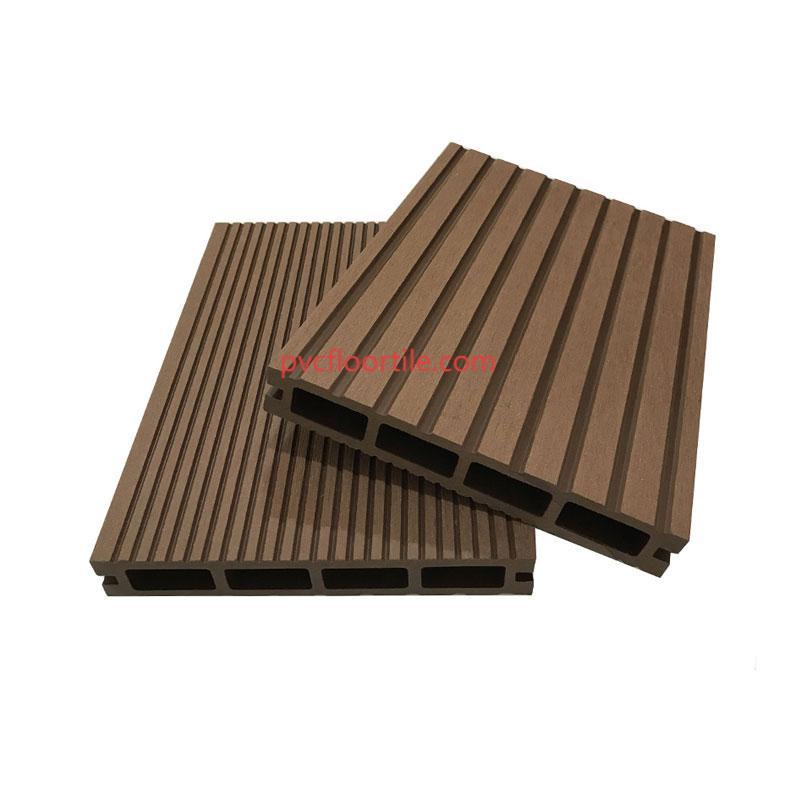

At Pvcfloortile, our procurement philosophy embodies this progressive interpretation of supplying responsibilities. We maintain that supplying superior materials constitutes just one component of our comprehensive service ethos. Collaborate with a WPC Flooring Supplier that regards client security and material purity as inseparable elements inseparable elements of professional service.Click https://www.pvcfloortile.com/product/ to reading more information.

- Creative Multimedia

- Education & Innovation

- Business & Technology

- Sustainability & Ethics

- App & IT Development

- Community & Culture

- Thought Leadership

- Мероприятие

- AI & Robotics

- Craft

- Кинозал

- Fitness

- Free Peck

- Игра

- Tutorial

- Health

- Music

- Networking

- Другое

- Business

- Religion

- Shop

- Sport

- Wellbeing