Securing Water-Pumping Stations along the Fergana Valley with Linear Base Seismic Isolation Rubber Bearing

The Fergana Valley’s intricate network of Soviet-era water-pumping stations keeps cotton, fruit and rice fields alive from Osh to Khujand, yet those same stations sit directly on the Talas-Fergana fault. A single strong-motion event could knock out pumps, crack pipelines and trigger regional food shortages. Engineers from Kyrgyzstan, Uzbekistan and Tajikistan are therefore uniting around one practical safeguard: the Linear Base Seismic Isolation Rubber Bearing. By placing a Linear Base Seismic Isolation Rubber Bearing layer between each pump house and its concrete footing, the station can remain operational even when the surrounding earth shifts by more than 200 mm.

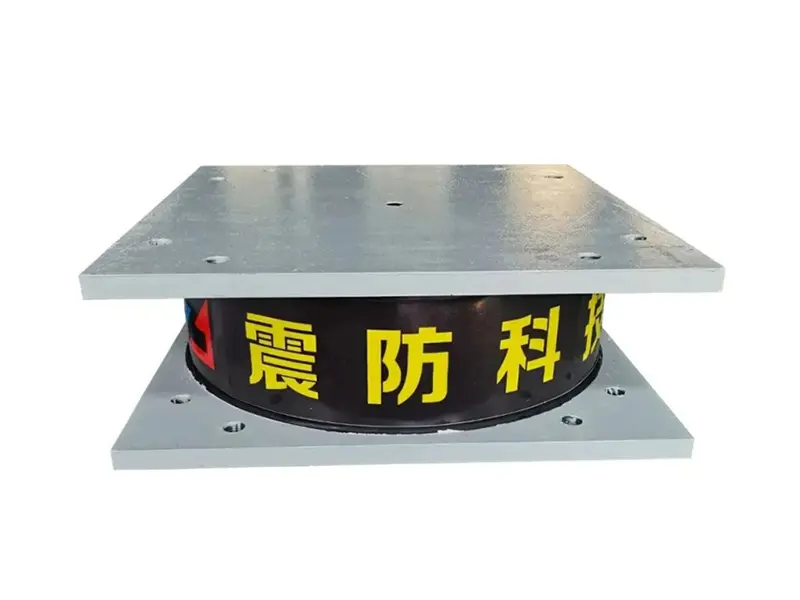

Each Linear Base Seismic Isolation Rubber Bearing consists of vulcanised natural rubber sheets interleaved with thin steel shims, creating a horizontally flexible yet vertically stiff cushion. During an earthquake the Linear Base Seismic Isolation Rubber Bearing allows the pump house to slide back and forth, effectively uncoupling the oscillations of the ground from the sensitive centrifugal machinery above. Because the Linear Base Seismic Isolation Rubber Bearing is moulded with a lead core, it also dissipates seismic energy through hysteretic damping, reducing peak accelerations felt by the pumps by up to 65 %.

Field tests conducted at the Kadamjai station in Batken oblast demonstrated that a set of 24 Linear Base Seismic Isolation Rubber Bearing pads could be installed beneath a 1970s pump house without interrupting irrigation for more than 72 hours. The Linear Base Seismic Isolation Rubber Bearing pads were pre-compressed, slid into position on temporary rails, and then released so that the entire building settled gently onto its new seismic isolation interface.

Economics strongly favour Linear Base Seismic Isolation Rubber Bearing technology. Replacing an entire pumping station after a quake would cost roughly US $2 million, whereas retrofitting with Linear Base Seismic Isolation Rubber Bearing averages only US $190 000. Moreover, the Linear Base Seismic Isolation Rubber Bearing system requires almost no maintenance once installed, because the rubber compound is formulated to resist the saline soils common in the valley.

Regional cooperation is now accelerating. A joint Uzbek-Tajik project funded by the Asian Development Bank will install Linear Base Seismic Isolation Rubber Bearing beneath ten critical stations along the Great Fergana Canal before 2027. By choosing Linear Base Seismic Isolation Rubber Bearing as its standard seismic intervention, Central Asia is not only protecting irrigation infrastructure; it is also safeguarding food security and social stability against the inevitable earthquakes of tomorrow.

Buscar

AI content

🤖 QuantumSync Insight

Loading...

Categorías

- Creative Multimedia

- Education & Innovation

- Business & Technology

- Sustainability & Ethics

- App & IT Development

- Community & Culture

- Thought Leadership

- Event

- AI & Robotics

- Crafts

- Películas

- Fitness

- Free Pecks

- Juegos

- Tutorials

- Health

- Music

- Networking

- Other

- Business

- Religion

- Shops

- Sports

- Wellbeing

Read More

Built for Extremes: The Industrial DC Current Electric Vibration Motor in Mobile and Hazardous Applications

From off-road concrete pumps to sub-sea trenching sleds, the Industrial DC Current Electric...

MMOexp: The dungeons of Dark and Darker reward

While this feature is often reserved for Dark And Darker Gold more experienced adventurers,...

Master the Wild West: The Power of Chips in GOP3

The allure of poker lies in its mix of strategy, bluffing, and a little bit of luck. In Governor...

Il futuro del gioco responsabile nei casinò online: Tendenze e iniziative del 2025

Il futuro del gioco responsabile nei casinò online: Tendenze e iniziative del 2025

Il...

Optimizing Cleanroom Performance with YD-Purification Systems

In sectors where environmental purity is crucial, Clean Room Doors And Windows serve as...