User Interaction Trends in Packaging Development

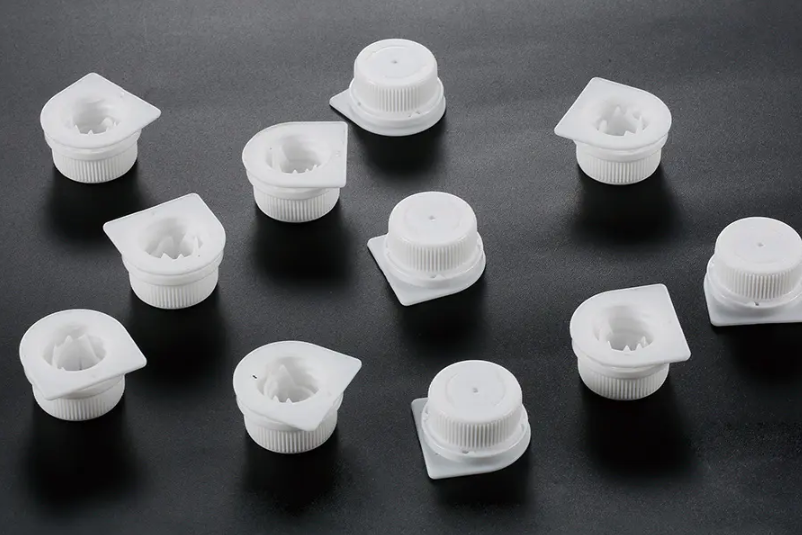

The versatility of a Multi-Use Bottle Cap continues to support product packaging across sectors, while the broader category of Plastic Packaging Bottle Cap remains essential for everyday consumer goods. Taizhou Tars International Trade Co., Ltd. works closely with global clients who require closures tailored to transportation, storage, and usage patterns. The design and selection of caps involve more than appearance—they directly influence product stability and functionality.

Manufacturers begin by assessing how the cap interfaces with the bottle’s neck finish. Thread patterns, torque range, and sealing surfaces play central roles in maintaining product integrity. Many consumer goods undergo repeated opening and closing cycles, making fatigue resistance an important factor in material selection. The plastic must maintain flexibility without weakening under stress.

Polypropylene’s balance of durability and moldability makes it a common choice for cap production. Variations in resin type allow manufacturers to enhance strength, clarity, or chemical resistance depending on the application. Taizhou Tars International Trade Co., Ltd. often collaborates with material suppliers to evaluate which resin grades perform well under customers’ specific conditions.

Different product categories benefit from different cap styles. Flip-top caps facilitate controlled dispensing for lotions, shampoos, and condiments. Their hinge mechanism requires precise engineering to prevent early breakage. Screw caps maintain strong closure strength and are commonly used for beverages, cleaning agents, and industrial liquids. Some caps include insert plug structures that improve internal sealing for thin liquids or volatile chemicals.

The tactile feel of a cap influences user interaction. Ribbing allows for better grip, especially when users’ hands are wet or oily. Smooth surfaces may be preferred for cosmetic products due to aesthetic expectations, while textured patterns support ergonomic handling. Designers pay attention to how caps feel during use, aiming for balanced resistance and comfortable rotation.

Safety requirements guide closure choices for certain products. Child-resistant caps rely on combined compression and rotational movements that require skill to open. Tamper-evident rings provide visible signs of first-time opening. These features depend on consistent molding and tight dimensional tolerances, which manufacturers must maintain across high-volume production.

Sustainability is an increasingly important consideration. Many brands seek to reduce material usage through lightweight caps, while others transition toward recyclable mono-material packaging systems. Mold designers analyze wall thickness, resin flow, and gate placement to support reduced material consumption without affecting performance. Taizhou Tars International Trade Co., Ltd. assists companies exploring eco-focused cap options by coordinating material testing and production evaluations.

Color plays a functional and aesthetic role. Caps may signal product variations or unify a product line visually. Pigment stability affects long-term appearance, especially for goods stored under strong lighting or temperature fluctuations. Manufacturers must balance visual goals with functional considerations such as UV stability and chemical compatibility.

Production efficiency influences cap design as well. Multi-cavity injection molds allow large quantities to be produced consistently. Cooling times, resin flow characteristics, and cavity balance impact the overall quality of the caps. Quality control measures—including torque checks, dimensional inspection, and fit testing—ensure caps perform reliably during filling, sealing, and transport.

Packaging designers also account for logistics. Products shipped through long-distance routes may face pressure changes, stacking weight, and temperature shifts. A Plastic Packaging Bottle Cap must remain stable throughout these conditions, preventing leakage or deformation. Some caps incorporate liners or sealing discs to support products that require additional protection.

Taizhou Tars International Trade Co., Ltd. provides support throughout the supply chain, from initial concept development to production follow-up. The company reviews manufacturing data, manages factory communication, and helps clients align cap designs with their filling machinery and bottle suppliers.

As consumer expectations evolve, caps adapt accordingly. Convenience-driven designs continue to gain attention, along with closures that offer smoother operation or improved dispensing control. Through collaboration between designers, material experts, and manufacturing teams, bottle caps evolve alongside the broader packaging landscape.

- Creative Multimedia

- Education & Innovation

- Business & Technology

- Sustainability & Ethics

- App & IT Development

- Community & Culture

- Thought Leadership

- Event

- AI & Robotics

- Craft

- Movie

- Fitness

- Free Peck

- Game

- Tutorial

- Health

- Music

- Networking

- Other

- Business

- Religion

- Shop

- Sport

- Wellbeing