Optimizing Injection Parameters for Plastic Cap Mold Efficiency

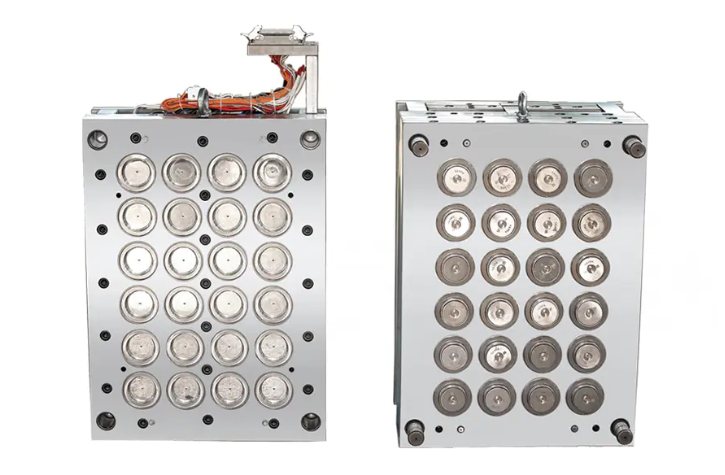

Plastic Cap Mold design is the first step toward high-efficiency closure production, yet many processors overlook the critical role that injection parameters play once the mold is bolted into the press. A Plastic Cap Mold may be built with the finest steels and hot-runner technology, but if melt temperature, injection speed, and holding pressure are not tuned to the specific resin, cycle times lengthen and part quality suffers. Experienced technicians start by profiling the Plastic Cap Mold cavity temperatures with thermal imaging; uniform heat distribution prevents premature crystallization in polypropylene and reduces sink marks on the top panel. The next variable is injection velocity: too fast and the Plastic Cap Mold risks jetting, too slow and the material freezes before the threads are fully formed. A balanced fill time of 0.6–0.8 seconds for a 29 mm beverage closure is a good benchmark for most Plastic Cap Mold layouts. Once the cavity is 95 % full, the machine transfers to pack and hold; here, a pressure of 600–700 bar for 0.8 seconds ensures that the Plastic Cap Mold impressions replicate every knurl and tamper-evident band detail. Cooling is equally decisive. Modern Plastic Cap Mold designs integrate bubblers and conformal channels that maintain a water temperature of 12–15 °C, extracting heat rapidly so that ejection can occur in under two seconds. When cycle consistency is paramount, scientific molding techniques such as in-cavity pressure sensors feed data back to the press, allowing automatic adjustments for viscosity shifts. In one documented case, a bottling plant shaved 1.2 seconds off its 4.8-second cycle after a systematic Plastic Cap Mold process window study, translating to 180 000 extra closures per day on a 48-cavity tool. Finally, operators must verify that the Plastic Cap Mold venting is adequate; clogged vents raise the required injection pressure and can degrade the resin, leaving black specks on the sealing lip. Regular preventive maintenance, including ultrasonic cleaning of vents and greasing of leader pins, keeps the Plastic Cap Mold running at the optimized parameters established during the initial validation run.

- Creative Multimedia

- Education & Innovation

- Business & Technology

- Sustainability & Ethics

- App & IT Development

- Community & Culture

- Thought Leadership

- Evento

- AI & Robotics

- Craft

- Filmes

- Fitness

- Free Peck

- Jogo

- Tutorial

- Health

- Music

- Networking

- Outro

- Business

- Religion

- Shop

- Sport

- Wellbeing